Server Services

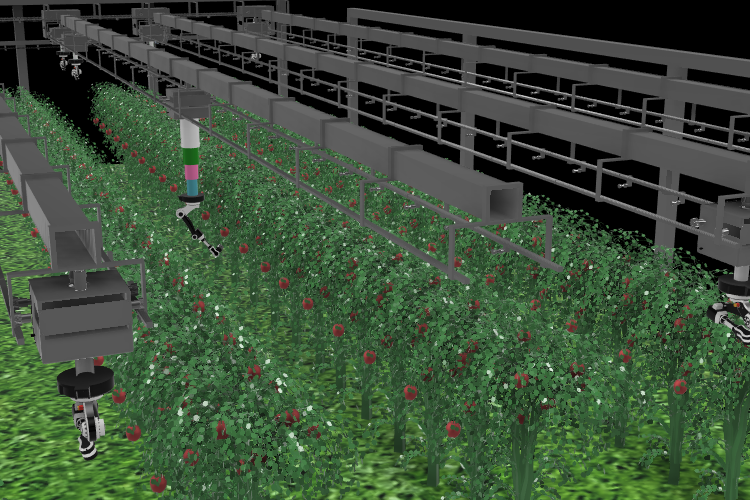

The automation of industrial processes and data management has triggered a

significant transformation in the manufacturing sector. In this transformation,

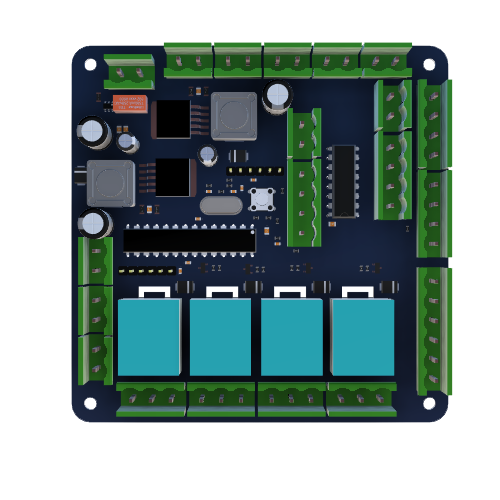

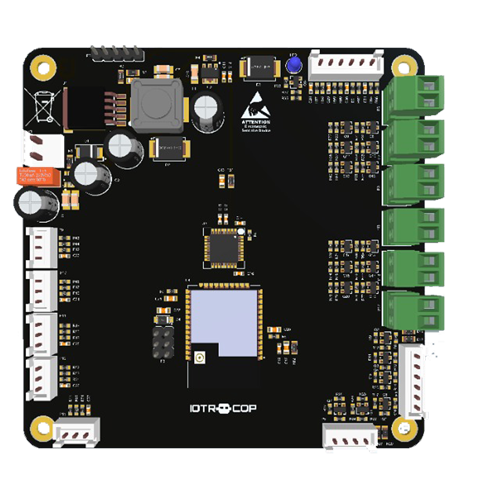

the role of servers holds critical importance. Servers undertake various tasks

such as managing workflow processes, collecting, analyzing, and sharing data

within factories. These servers collect and monitor data generated by sensors

and other devices present in factories. This data enables real-time monitoring

of production processes. For instance, performance data of manufacturing

machines such as temperature, pressure, and speed can be collected and

evaluated through servers.

-Servers communicate with automation systems to manage production

processes. They can control the operation sequence, speed, status, and

settings of machines on the production line. As a result, human intervention

is reduced, and processes are managed more accurately and efficiently.

- It is essential to securely store and back up data generated in factories.

Servers play a crucial role in centralizing and making this data accessible by

storing it in a centralized repository.

Regular backups are also performed through servers to prevent data loss

- Servers enable factory systems to connect to the internet and provide remote access.

This facilitates remote diagnostics by experts and simplifies maintenance and update procedures.

Additionally, servers play a crucial role in ensuring the cybersecurity of factories. They take

measures to protect against internal and external threats, monitor

the security status of the system, and implement precautions against potential attacks

In this context, as our software team, we assist you in shaping the future of your factories.

By designing software solutions tailored to the specific needs of your

business, we enable you to harness the full potential of servers.